PLEASE NOTE: Part 1 of The Grapes Are in the House! was posted here yesterday. The story continues…

September 15 - Merlot harvest for commercial wine

There’s a famous vineyard just north of Sonoma that claims to take advantage of the geothermal activity in that area. Specifically, the fact that the temperature of the soil is warmer than elsewhere, providing enhanced growing conditions and even protection from frost. Sounded pretty awesome to me and in May I inquired about securing a ton of Merlot, their signature varietal.

I can’t say my request was met with enthusiasm. In fact, I had to follow up a couple of times just to get someone to review my order and schedule a vineyard tour. Understand that a one-ton order to a larger commercial vineyard is more of a pain in the butt than it’s worth, and most won’t write that small of a contract. I got that, and I had my own misgivings with the fact that they were a larger commercial outfit—not exactly in keeping with my Tiny Vineyards ethos.

Still, I was intrigued with the unique terrior and wondered if maybe they had a separate, small block of amazing Merlot somewhere on the property that could qualify as a stand-alone “tiny vineyard.”

Big, unrealistic ask, I know. But it turned out they actually kind of did.

Seems there were a few rows along the edge of a large block of Merlot that were very old vines that no longer produced the yield needed to be commercially viable. I could buy grapes from there if I wanted, but the company planned to rip these vines out and replant within a couple of years.

Whoa! This was exactly in Tiny Vineyards’ wheelhouse. What old vines lacked in yield they often made up for in greater concentrations of phenolics—i.e., flavor! At least that’s the conventional wisdom, and I was ready to give it a shot.

Then it began to get hot outside.

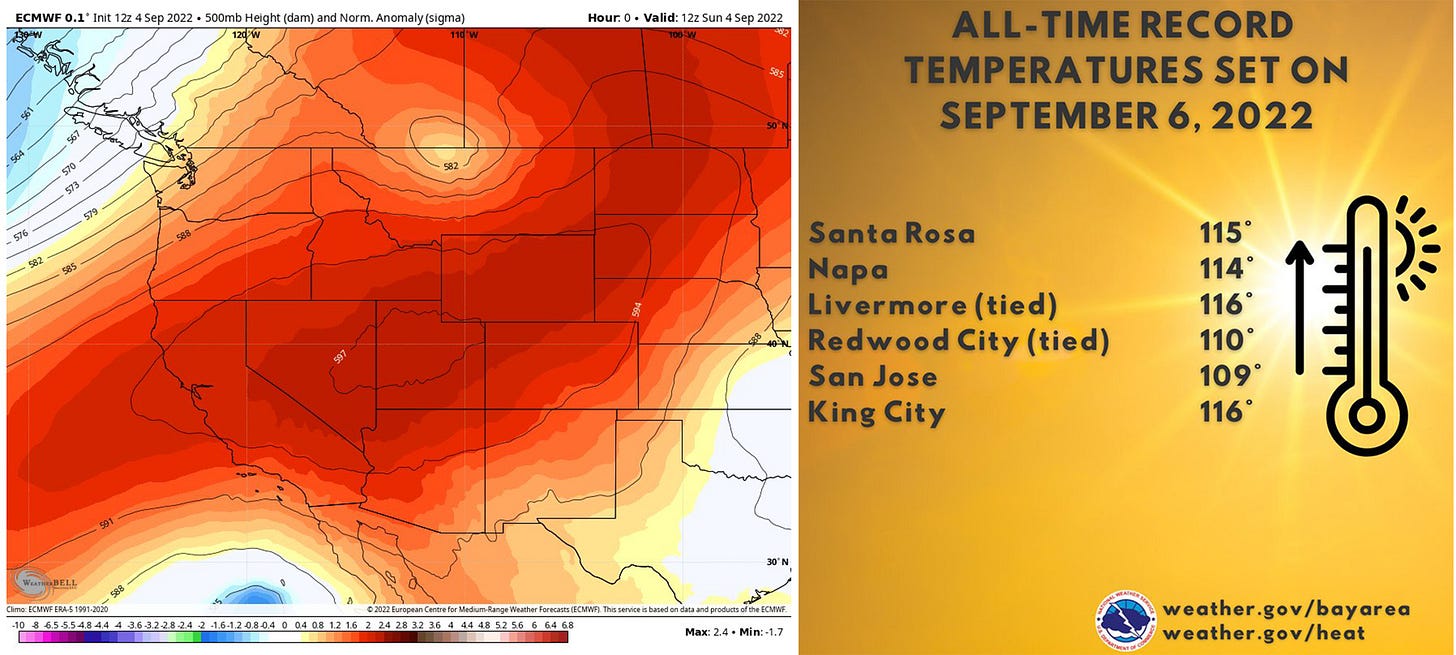

The heat dome hit Sonoma on September 3rd, peaking on the 6th with record high temperatures throughout wine country. I had tested Merlot samples just four days before and had gotten 23°Brix, 3.39 pH. Darn near perfect chemistry. I enquired with the vineyard right then about picking soon, and heard back, “You call the pick so you tell us when you want the fruit.”

A week later—right in the middle of the heat dome—I enquired again about what kind of sugars they were getting. “We got 25 but there is no color and it is definitely not ready. No one is picking yet. we’re thinking the week after next.”

I chewed on this for a couple of days and couldn’t get the worried taste out of my mouth. I replied back, “The Brix in my row is up another point, the pH continues to rise, and I’ve got a lot of brown seeds. It may be that my row is ripening faster as perimeter rows often do, but ripe it is.” I alluded as to how I thought we should pick immediately.

I eventually heard back, “As you can imagine when harvesting hundreds of tons of fruit things change regularly especially when a buyer of 100 tons of fruit calls. We are going to have to make Thursday work for your one ton of fruit. I appreciate you working with us on this.”

Okay, so now I knew where I stood.

That afternoon—just two days after the heat dome—I sent a new sample to the lab. It came back 29.4° Brix, 3.69 pH, with a TA of 4.68.

Holy sh—t! What just happened?

That Thursday morning my one ton of Merlot showed up at Magnolia just as promised. We crushed it and cold soaked it for a couple of days, and the Brix did drop back down a little to 27.5°, but the pH continued to rise to 3.86 and the TA dropped further to 3.76. I adjusted the must with 3 g/L of tartaric acid and three days later we watered back with 17 gallons of H2O—something I’ve been resistant to since day one.

So yeah, I was a little miffed. I mean, you jump through hoops to extract as much aroma and flavor and color in your wines only to dilute your efforts with water because you picked your grapes too late?! Not to mention the $5,000 per ton on average it takes to turn grapes into wine.

Of course, I know it’s not as simple as that—what with the weather being as whacky as it is—and so I’ve purposely not identified the vineyard I purchased my Merlot from, or anyone I worked with there. They only have—what—a gazillion more years of experience than I do? And this may all still turn out just fine, with great Merlot being made because they followed the correct harvest protocol, forcing me to do the same in the cellar.

Plus, I’ve got to live in this town and prosper in this industry. So it makes little sense to burn any bridges. Confucius say, “Humility is the solid foundation of all virtues.” Yogi Berra say, “It ain't the heat, it's the humility.”

September 17 - Change of plans #2: Cabernet Sauvignon harvest for commercial wine, and Sangiovese harvest for personal/client wine

The text notification buzz on my phone woke me at 5:00 a.m. Swimming to the surface of consciousness I fumbled for my phone and finally got my one good eye to focus.

Joe, this is Brad. We’ve got a problem. My picking crew never showed. Call me when you wake up.

Brad owns and farms a spectacular one-acre Cabernet Sauvignon vineyard in Sonoma. He’s determined to raise both the awareness and the price of Sonoma Cabernet to levels on parity with that of Napa, our snooty neighbor to the east. While I’m not so sure he’ll ever command such a price, I think the quality might be there, especially after sharing a luscious bottle of Cab made from his grapes by his winemaking pal in Marin.

Brad’s grapes are our most expensive ton-rate this year by a mile, and we’ve committed to 3,000 pounds. So, his text got my attention. The evening before I had dropped off a pickup truck with tailer and three half-ton macro bins. The plan was that he and his crew would pick through the night, after which I would come get the truck and drive the grapes to Magnolia for processing. Then I would join everyone else for our only volunteer-group-pick of the year harvesting a half-ton of Sangiovese from our “rescue” vineyard in Glen Ellen.

With seven volunteers—my son Penn and his fiancé Lia driving up from San Francisco, my business partner Bruce who had flown in from Colorado the day before, Wade Hutchins, stalwarts Tom McKean and Kelly Feehan, and of course picker par excellence Deb—the harvest would be easy and fun. We planned a big sugary breakfast spread of coffee and pastries, and another food and wine fest for lunch after we had crushed the fruit.

Now, suddenly, everything was out of balance.

I called Brad back and winced at his exhausted voice. He and three friends, rushed into service at the last minute, had been picking all night but were still only about halfway through. His professional picking crew had simply not shown up, even though they had called the evening before to confirm that they’d be there. He was at his wits end, to say the least.

“Brad, hang tight man,” I responded. “I might be able to solve this. I’ve got a crew of pals showing up at another vineyard at 8:00 a.m. for a volunteer pick. Let me see if I can contact everyone and divert them to here first, and we’ll make short order of what’s left.”

A flurry of texts, emails and phone calls eventually reached everyone and pointed them in the new direction. By 10:00 a.m. we had 3,235 pounds of Sonoma’s finest Cabernet packed into three overflowing bins headed to Magnolia.

Bruce and I took the Cabernet Sauvignon grapes to Magnolia and then returned the rental truck and trailer, while everyone else headed up to Glen Ellen to Hassan’s vineyard, also known as our “rescue vineyard.” This little Sangiovese vineyard of 275 vines had been severely damaged when wildfires swept through the area in 2017. I’ve been working to restore it for the past few years, and this was payback year. Extensive pruning and replanting had breathed life back into the vineyard and it was now chock full of grapes, due in large part to the efforts of Tom McKean and Deb figuring out how to effectively apply bird netting.

The netting had worked and taking it back down was the first order of the morning as our picking crew swept in after its warmup session picking Brad’s Cabernet. By the time Bruce and I got back from dropping off grapes, truck and trailer, the lion share of the work had been done.

Everyone then headed to my backyard winery at Bobbies and quickly crushed the 1,000+ pounds of Sangiovese the vineyard had yielded (compared to about 200 pounds last year!). It was the biggest day yet for associates of the Tiny Vineyards Wine Company, and it felt good that we had been able to shift gears and take care of what needed to get done. Many thanks to everyone involved!

September 21 - On to pressing matters, Bobbie’s Malbec

The thing about harvest is it isn’t just about harvest. Once the grapes have been picked, and crushed, and slopped into a fermenter, then you’ve got to sweat through usually a couple of weeks or more of literally a gazillion (160 million/mL is optimal) fragile little one-celled fungi chowing down on the sugar in your grape juice and puking, pooping, peeing—whatever—it back as ethanol. Yep, that’s the basic process. Lots of things can go wrong here, and they often do, but if you can keep those little yeasty beasties alive long enough, they’ll eventually find themselves on a zero sugar diet (because there’s none left), and that pretty much does them in, as it would me.

Then the whole sloppy, soupy mess, which we’ve been calling “must” up until now is poured into some type of press which squeezes the liquid—which we can now suddenly call “wine”—from all the grape skins, stems, seeds, dead yeast cells, MOG (material other than grapes), etc., now formally known as “pomace.” This nomenclature lesson is usually a lot of fun as the literal fruits of your efforts are realized.

Our first press of the season was our Chardonnay on August 22 (watch the video, it’s cool!). But that was early and different, and not at all like a red wine press. Our first red grape harvest to get pressed, Bobbie’s Malbec, was a month later on September 21.

There’s something sensual, and primordial, and oddly religious about the blood-like new wine pouring from my old 45-gallon basket press. It always kind of messes me up, and I find myself quietly reciting the Mass in Latin—vestiges of my early days as an altar boy. Weird, I know. But when your first memory of the smell of wine was the priest’s breath as he gave you communion—that’s powerful stuff.

September 24 - Picking Peter’s Ribolla Gialla

It’s not like we don’t have anything to do. But, when a pal is trying to put together a crew to pick grapes you gotta ride for the brand. Plus, if it’s Peter Stanford making the summons, you know there will be plenty of great coffee and maple bacon donuts from Dirty Girl. Plus he always has too many people which turns the harvest from a chore into a fun social event. Deb and I have been part of his crew for years.

Coming tomorrow:

The Grapes Are in the House! - PART 3 The final installment of the story of this year’s harvest. We’ll be going deep into our efforts to bring in 10 tons of grapes, and how we mitigated the effects of a massive heat dome followed by full scale deluge.